Built for Servers. Powered by Service.

Performance and reliability are vital for businesses. Kingston’s proven experience, recognized best practices, and trusted industry leadership make our products the smart choice.

A journey to unparalleled reliability

In the ever-evolving world of memory technology, the importance of comprehensive testing cannot be overstated. Kingston, a name synonymous with quality and reliability in the memory industry, is a prime example of a company that has mastered the art of testing dynamic random-access memory (DRAM). In this article, we will delve into our intricate process of DRAM testing, exploring how we have set ourselves apart from competitors and established industry standards for quality assurance.

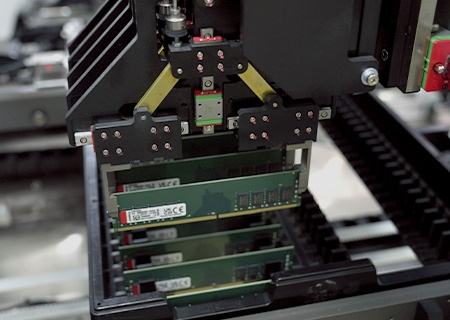

At Kingston, rigorous testing begins long before a product reaches the hands of customers. It encompasses various stages, from component characterization and module design verification to reference platform validation. This extensive pre-production phase ensures every aspect of the memory module is thoroughly evaluated before going to mass production.

Once in production, our testing process requires 100% testing of all memory modules. We use a combination of off-the-shelf motherboards and proprietary test systems, with a test suite that mirrors real-world applications. This sets us apart from typical DRAM semiconductor companies, who often limit their testing to specification checks.

For ECC-enabled server-class modules, Kingston utilizes a patented Dynamic Server Burn-In process. Here, the DRAM module is pushed to its limits, deliberately stressing an equivalent of three months of heavy utilization in a 24-hour period to force potential early-life failures to manifest under our roof, and not that of our customers.

This dedication to early failure mitigation is a testament to our unwavering commitment to quality and reliability. As technology advances, so do our testing methods, with constant refinement and innovation at the heart of our approach.

Kingston’s Quality Assurance team manages an extensive check and balance process to ensure the integrity of our memory modules and manufacturing processes are up to standard. Over 35 quality control checkpoints are integrated into Kingston’s manufacturing, testing, packaging, warehousing, and shipping processes. At each checkpoint, independent verification of product quality is measured and reported. Kingston employs a combination of automated optical scanning systems and dedicated quality control technicians to sample and verify adherence to our quality requirements. For testing, this means that after 100% production testing is complete, a statistical sample from the production lot is pulled and re-tested. Compliance to our strict quality requirements is monitored by quality engineers, who regularly audit our procedures and systems to ensure our best-in-class practices are being upheld.

Our testing team works closely with chipset architects like Intel and AMD, as well as major motherboard brands, to evaluate next-generation hardware and firmware, ensuring our production test systems are always ready for the future. We even develop proprietary, internally designed automated systems to stay at the forefront of high-volume manufacturing.

While two DRAM chips from competing suppliers may have identical specifications, each DRAM die possesses its own unique brand characteristics. We leverage our strong relationships with the world’s leading DRAM suppliers—Micron, SK Hynix, and Samsung—to ensure the DRAM components we use meet our stringent requirements for reliability and performance. Having a strict component qualification process ensures consistency among our suppliers, delivering a higher-quality product to our customers with a diverse supply base, and in turn helping our suppliers improve their products with our comprehensive feedback of ongoing quality metrics.

Our combination of off-the-shelf and proprietary memory testing software and hardware sets Kingston apart from not only our DRAM semiconductor suppliers, but also our module house competitors. This expertise in testing and attention to quality has enabled Kingston to become a world-class contract manufacturer for major OEMs and the world’s largest data centers for nearly three decades. During this time, we accumulated a wealth of experience and insights and combined our best practices with those of our contract customers to create an unparalleled aggregate of expertise found nowhere else in the industry.

Initiated in 2004, Kingston’s patented Dynamic Server Burn-In process has evolved over the decades in tandem with DRAM technology. Initially developed to combat early-life semiconductor failures that could manifest in the first 90 days of use, the process utilized custom high-temperature ovens to force potential defects to manifest during the testing process. Since then, the process has been reengineered to burn in at the testing stage, where temperature, voltage, and software workloads are dynamically and precisely controlled to expose an early-life failure. This evolution and commitment to continual improvement has been critical to adapting to the ever-shrinking semiconductor.

Our 100% testing sets us apart from our competitors, our DRAM suppliers, and module house vendors. While the industry standard often relies on multi-million-dollar Automated Test Equipment (ATE) systems for component/module specification testing, at Kingston we go beyond and use off-the-shelf hardware with real-world application testing, mirroring what customers use, to ensure higher quality and reliability. Kingston's focus on quality, backed by our lifetime warranty, to provide affordable, guaranteed compatible memory solutions for major OEM systems, gives us an edge to stand out among a crowd of competitors.

Kingston's testing methodologies constantly evolve to meet the demands of an ever-changing market. Our involvement in industry standardization through organizations like JEDEC reflects our dedication to shaping the future of memory technology.

Kingston's extensive testing directly impacts our customer’s value proposition. Data centers, in particular, benefit from the demonstrated reliability and low field failure rates. End users appreciate Kingston’s compatibility, lifetime warranty, and excellent support.

Kingston's consistent dedication to quality assurance is a testament to our commitment to providing the best possible memory solutions. Customers, whether they prioritize compatibility, reliability, or affordability, can trust Kingston to deliver memory products of the highest quality.

In a world where the performance of computers and servers hinges on the reliability of DRAM, Kingston stands as a beacon of excellence. Our unwavering commitment to testing and quality assurance has set industry standards and continues to provide customers with memory products that can be relied upon without hesitation. Kingston's journey through the intricate world of DRAM testing is a testament to our dedication to perfection.

#KingstonIsWithYou

Performance and reliability are vital for businesses. Kingston’s proven experience, recognized best practices, and trusted industry leadership make our products the smart choice.

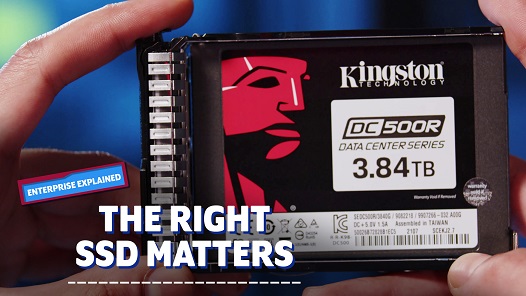

Choosing the right SSD is important since not all SSDs are alike. When it comes to data centers, choosing an SSD with the right performance consistency with low latencies that’s specifically built for enterprise and data center workloads is key for consistent and reliable performance.

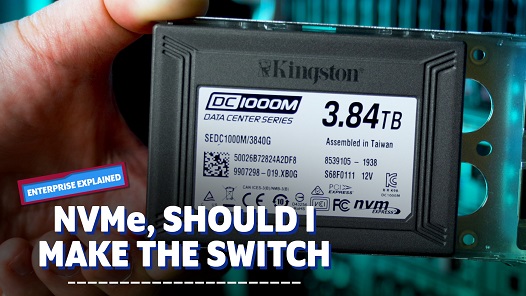

With the rise of data, need of edge computing and edge networks data center upgrades with NVMe SSDs enable more possibilities than before.

SSDs are all alike, right? You plug it in and instantly have all of that Flash Memory available for your workload? Right? If you answered yes, then you’ve probably fallen to one of the 4 biggest mistakes you could make when selecting your SSD.

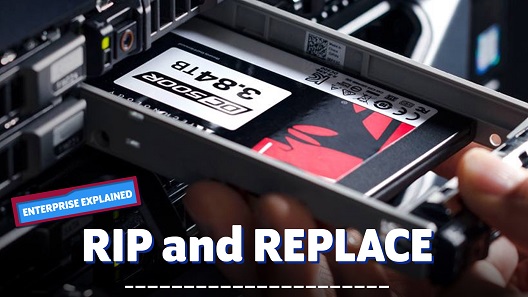

Some enterprises still make use of client SSDs to handle high-intensity server tasks, then rip & replace them when they fail to maintain the required standard of performance. Learn why that’s a false economy and how enterprise-level drives can increase organizational efficiency.

When you start with Kingston, choosing memory is easy.

With over 35 years of expertise, Kingston has the knowledge and resources you need to choose memory with confidence.

Simply enter the make and model number or system part number of the computer system or digital device to find the Kingston products you need.

Search by either the Kingston part number, distributor part number or manufacturer equivalent part number.