CAMM stands for Compression Attached Memory Module and is a new memory module form factor designed for thin-profile laptops or all-in-one systems. Initially a Dell proprietary design, in late 2022 the CAMM concept was introduced by Dell to JEDEC, the industry standards body for memory modules, to create a new standard for anyone to use.

Initial designs for the industry-standard CAMM, called CAMM2, were made available in late 2023 for computer and memory module manufacturers to adopt, with additional designs in development slated for release by the second half of 2024. The challenge to any new memory design is always standardisation and adoption by the industry, particularly chipset architects (Intel, AMD). Dell’s investment and willingness to share their design royalty-free with the JEDEC standards body is a testament to their commitment to standardisation.

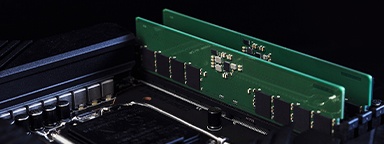

Instead of leads on the bottom edge of the conventional memory module that plug into a socket, the CAMM uses a compression connector that mounts to a thin interposer on the motherboard. Screws are then used to secure the CAMM in place. A CAMM can be single sided to reduce z-height to accommodate a very thin profile system, with options for the width and length of the CAMM module to support higher memory capacities. The JEDEC CAMM2 designs support different types of memory components (DDR5 and LPDDR5/X), which provide flexibility for manufacturers to choose the right memory type for their systems.